First, let's understand why CCD automatic positioning is needed.

Traditional screen printing relies on manual visual alignment and fixtures, resulting in significant errors and low efficiency. In contrast, CCD cameras can automatically recognize the fiducial marks (registration holes or markers) on the sheet material, calculate precise offset values, and automatically adjust the screen position to achieve accurate registration.

For materials that exhibit slight deformation or positional variations in each piece due to processes like punching or injection molding, CCD systems can individually compensate and correct for each piece, which is impossible to achieve manually.

Automated alignment is fast, reduces manual intervention, is particularly suitable for high-volume production, and significantly lowers the rejection rate caused by misalignment.

It reduces the dependency on operator experience; even novices can produce high-quality products after simple training.

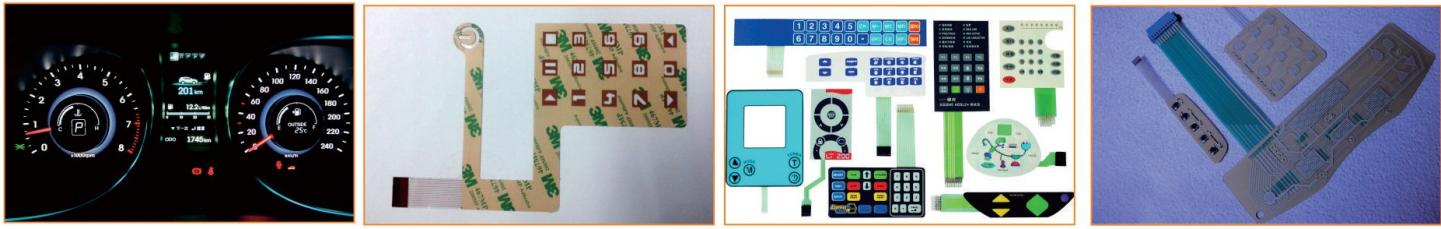

Next, let's look at the application fields of CCD automatic positioning sheet screen printing machines, they are primarily used in industries with stringent requirements for printing position accuracy and color registration accuracy, as detailed below:

Electronics and Semiconductor Industry - The most widespread and demanding field for CCD screen printing machines, e.g.,

Printed Circuit Boards (PCBs): Used for printing solder masks, character markings, conductive silver paste, etc., on PCBs.

Touch Panels and Displays: Printing borders, electrodes, decorative patterns, etc., on ITO glass or PET films.

Solar Cells: Printing back electrodes and grid lines on solar cells, requiring extremely high conductivity and precision.

Electronic Components: Printing identifiers, codes on components like crystals, chips, resistors, capacitors.

Mobile Phone/Computer Components: Printing text and patterns on mobile phone casings, keyboards, internal structural parts.

Automotive Industry:

Automotive Instrument Clusters: Printing scales, symbols, backlit panels on dashboards.

Interior Parts: Printing on window switch panels, decorative trim covers.

Lights: Printing patterns and logos on tail lights, turn signals.

Home Appliance Industry:

Control Panels: Printing graphics and text on control panels of appliances like washing machines, microwaves, air conditioners, refrigerators.

Decorative Panels: Printing brand logos, decorative patterns on appliance housings.

Plastic Products Industry:

Cosmetic Packaging: Printing intricate patterns and logos on containers like lipstick cases, compact powder cases, lotion bottles.

Medical Devices: Printing scales, markings on syringes, test tubes, diagnostic test strips. Requires high standards of cleanliness and precision.

Daily Use Items: Credit cards, membership cards, gift cards, toys, etc.

Advertising and Signage Industry:

Acrylic Signs: Manufacturing high-end store signs, directional signs, plaques, etc.

Metal/Aluminum Plates: Nameplates for instruments and equipment, brand labels, etc.

Finally, let's examine the suitable product types for printing?

The term "sheet screen printing machine" indicates its workpiece is sheet or plate-like material, primarily categorized by material and form:

Product Material:

Plastic Sheets: PVC, PET, PC, PMMA (Acrylic), ABS, etc.

Metal Sheets: Aluminum plates, stainless steel plates, copper plates, etc.

Glass Sheets: Flat glass, optical glass, etc.

Composite Materials: Copper-clad laminates (PCB substrate), ceramic sheets, etc.

Paper and Cardboard: High-end packaging, greeting cards, special paper labels.

Product Form:

Regular Sheets: Square LCD panels, rectangular circuit boards, round lenses, etc.

Irregular/Shaped Sheets: Products pre-formed into irregular shapes through die-cutting, such as mobile phone casings, irregularly shaped signs, automotive buttons, etc. This is precisely where CCD systems excel, as they do not rely on physical borders for positioning but use visual recognition.

If your industry or product meets the following characteristics, then a CCD automatic positioning screen printing machine is undoubtedly an excellent choice for enhancing your production capacity and product quality, as its core value lies in solving the need for "high precision" and "high efficiency" in automated printing:

The product has high value, and scrap costs are significant (e.g., high-end PCBs, displays).

Production batches are large, requiring high production cycle rates.

The product itself has inherent, unavoidable deformation or positional tolerances (e.g., stamped parts, injection molded parts).

Printing tasks require multiple precise color registrations.

Contact: Bruce Lee

Phone: 13714371086

Email: hnlyxiaolong@163.com

Add: Room 203, 2nd Floor, Building 1, Yongshengfa Technology Park, No. 28 Daxing Road, Dalingshan Town, Dongguan City, Guangdong Province, China